Office #207-2nd Floor-ZALFA BUILDING-NEAR Jumeirah Creekside Hotel-Garhoud -Dubai UAE

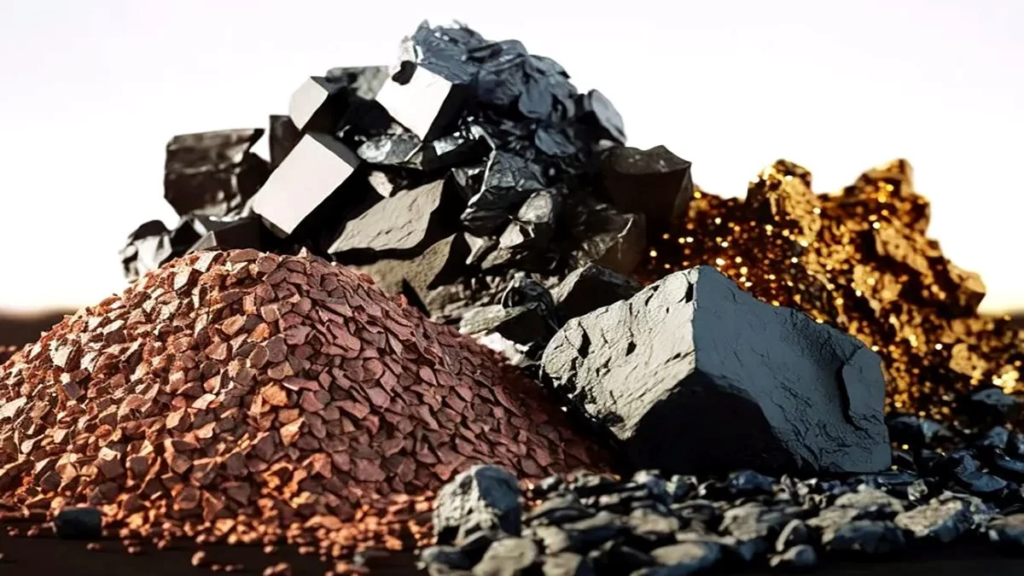

Metals Exporter UAE MKK Trade is a leading metals exporter in the UAE, providing high-quality aluminum, copper, steel, and specialty alloys to global markets.

MKK Trade, a significant exporter in the UAE’s robust metals market, plays a crucial role in facilitating the export of a wide range of metals to international markets. The UAE is strategically positioned as a global hub for metals trading due to its advanced infrastructure, favorable business environment, and access to key global trade routes. MKK Trade has capitalized on these advantages to become a major exporter of both ferrous and non-ferrous metals, serving industries that rely on these raw materials for manufacturing, construction, and technological applications.

Export of Ferrous Metals

A key area of MKK Trade’s focus is the export of ferrous metals, which include steel, iron, and other alloys that contain iron. Steel, for example, is in high demand worldwide for its use in infrastructure projects, from buildings and bridges to pipelines and machinery. The UAE, with its modern steel manufacturing facilities, produces a wide range of steel products, including rebar, sheets, and structural steel components. MKK Trade facilitates the export of these products to regions such as Africa, the Middle East, and Southeast Asia, where infrastructure development is booming. The company’s deep knowledge of logistics and market demand allows it to efficiently connect buyers with UAE-produced ferrous metals, ensuring timely and cost-effective deliveries.

Non-Ferrous Metals: Aluminum, Copper, and Zinc

In addition to ferrous metals, MKK Trade is heavily involved in the export of non-ferrous metals, which are metals that do not contain iron and are resistant to rust and corrosion. Among these, aluminum is a key export for MKK Trade, thanks to the UAE’s dominance in global aluminum production. Emirates Global Aluminium (EGA), one of the world’s largest aluminum producers, supplies high-quality aluminum for use in industries such as automotive, aerospace, construction, and packaging. MKK Trade exports this versatile metal to various international markets, where it is valued for its light weight, strength, and durability.

Copper and zinc are also important components of MKK Trade’s portfolio of non-ferrous metals. Copper, a highly conductive metal, is essential for electrical wiring, telecommunications, and the production of electronic components. Zinc is commonly used for galvanization, which protects steel and iron from rusting, and is a key material in the automotive and construction industries. MKK Trade’s access to these metals allows it to meet the global demand for materials that are essential for modern infrastructure and technology.

Strategic Use of UAE’s Logistics and Trade Hubs

One of MKK Trade’s biggest strengths as a metals exporter is its ability to utilize the UAE’s world-class logistics and trade hubs. The UAE’s ports, such as Jebel Ali Port in Dubai, are among the busiest and most efficient in the world, allowing MKK Trade to handle large volumes of metal exports. These ports provide direct access to major shipping routes, connecting MKK Trade to markets across Europe, Asia, and Africa. Additionally, the UAE’s free zones, including the Jebel Ali Free Zone (JAFZA) and the Dubai Multi Commodities Centre (DMCC), offer business-friendly environments with streamlined customs processes, enabling MKK Trade to export metals quickly and efficiently.

MKK Trade also benefits from the UAE’s strong air freight infrastructure, which allows it to deliver time-sensitive or high-value metals to customers in distant markets. This flexibility in shipping methods gives MKK Trade a competitive edge, as it can offer customized solutions to meet the specific logistical needs of its clients.

Commitment to Quality and Global Standards

MKK Trade’s success as a metals exporter is also driven by its commitment to quality and adherence to international standards. The metals exported by MKK Trade are sourced from reputable producers in the UAE and undergo rigorous testing and quality control measures to ensure that they meet the specifications required by customers in industries such as construction, manufacturing, and technology. The company’s reputation for delivering high-quality products has helped it establish long-term relationships with clients across the globe, from major construction firms to automotive manufacturers and electronics companies.

MKK Trade’s focus on sustainability is another key factor in its success. As global demand for environmentally responsible materials grows, MKK Trade has positioned itself as a supplier of metals that are produced using energy-efficient and environmentally friendly methods. The UAE’s aluminum industry, for example, is known for its efforts to reduce emissions and energy consumption, making aluminum from the UAE an attractive option for buyers who prioritize sustainability.

Meeting Global Market Demands

MKK Trade’s ability to adapt to the changing needs of the global metals market has been crucial to its growth. The company closely monitors global trends in metals demand, including the increasing need for raw materials in emerging markets, the expansion of renewable energy infrastructure, and the growing use of advanced materials in technology and manufacturing. By staying ahead of these trends, MKK Trade is able to offer the right products to the right markets at the right time, ensuring that its customers have access to the metals they need to fuel their growth.

In conclusion, MKK Trade’s role as a metals exporter in the UAE is characterized by its ability to source high-quality ferrous and non-ferrous metals, leverage the UAE’s world-class logistics infrastructure, and maintain a strong commitment to quality and sustainability. These strengths have made MKK Trade a key player in the global metals market, serving a wide range of industries and contributing to the UAE’s reputation as a leading hub for international trade.

The types of metals that MKK Trade exports, including their properties, uses, and significance in various industries:

1. Aluminum

- Properties: Lightweight, corrosion-resistant, malleable, and has good thermal and electrical conductivity.

- Uses: Commonly used in construction (window frames, roofing), transportation (aircraft, automobiles), packaging (cans, foil), and electrical applications. Aluminum’s recyclability also makes it environmentally friendly.

2. Copper

- Properties: Excellent electrical and thermal conductor, ductile, and resistant to corrosion.

- Uses: Widely used in electrical wiring, plumbing, roofing, and industrial machinery. Copper is also essential in the production of alloys such as bronze and brass.

3. Steel

- Properties: Strong, durable, and versatile; comes in various grades and types (e.g., carbon steel, stainless steel).

- Uses: Utilized in construction (beams, rebar), automotive manufacturing (frames, body panels), appliances (washers, dryers), and machinery. Stainless steel, in particular, is valued for its corrosion resistance and aesthetic appeal.

4. Zinc

- Properties: Corrosion-resistant, low melting point, and can be easily alloyed with other metals.

- Uses: Primarily used for galvanizing iron and steel to prevent rust. It is also used in die casting, producing alloys, and making batteries (especially in alkaline batteries).

5. Brass

- Properties: An alloy of copper and zinc, known for its malleability and resistance to corrosion and tarnishing.

- Uses: Commonly found in plumbing fittings, musical instruments, and decorative items. Brass is also used in electrical connectors and terminals due to its conductivity.

6. Lead

- Properties: Dense, malleable, and resistant to corrosion, but toxic if ingested or inhaled.

- Uses: Primarily used in batteries (especially lead-acid batteries), radiation shielding, and soldering. Lead is also used in some types of glass and ceramics.

7. Nickel

- Properties: Strong, ductile, and resistant to corrosion and heat; it can also be alloyed with other metals to enhance their properties.

- Uses: Used to make stainless steel and other alloys, coinage, and batteries (particularly rechargeable batteries). Nickel is crucial in the aerospace and automotive industries for its high-temperature resistance.

8. Titanium

- Properties: Lightweight, strong, and highly resistant to corrosion and extreme temperatures.

- Uses: Frequently used in aerospace (aircraft frames, jet engines), medical devices (implants, surgical instruments), and high-performance sports equipment. Titanium’s biocompatibility makes it ideal for medical applications.

Significance of Metal Exports

The export of these metals is crucial for various global industries, as they are foundational materials for construction, manufacturing, and technology. By exporting high-quality metals, MKK Trade not only contributes to the economy but also supports international trade and industrial growth.

Overall, MKK Trade’s commitment to exporting a diverse range of metals positions it as a key player in the global supply chain, catering to a wide variety of industries and helping meet the demands of modern infrastructure and technology.

Metal suppliers UAE Steel exporter UAE Aluminum exporter UAE UAE metal importers Bulk metal wholesale UAE Copper exporter UAE Best metals exporter UAE UAE metal manufacturers and suppliers Premium quality metals UAE Iron and steel exporter UAE Metal scrap exporter UAE Aluminum and steel export to Dubai UAE metal products distributor Non-ferrous metal exporter UAE Bulk metal import regulations UAE High-quality metal for UAE industries UAE construction metal suppliers Stainless steel suppliers UAE UAE heavy metals importers Best quality metal supplier in UAE Exporting aluminum and steel to UAE Copper and brass metal exporters UAE How to import metals to UAE Top UAE distributors for metal products Types of Metals Aluminum Properties: Lightweight, corrosion-resistant, malleable. Uses: Construction, transportation (aircraft, vehicles), packaging (cans, foils). Copper Properties: Excellent electrical and thermal conductor, ductile. Uses: Electrical wiring, plumbing, roofing, industrial machinery. Steel Properties: Strong, durable, versatile; comes in various grades (carbon, stainless). Uses: Construction (beams, rebar), automotive (frames, body panels), appliances. Zinc Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Properties: Corrosion-resistant, low melting point. Uses: Galvanizing steel, die casting, batteries. Brass Properties: Malleable, corrosion-resistant alloy of copper and zinc. Uses: Plumbing fittings, musical instruments, decorative items. Lead Properties: Dense, malleable, resistant to corrosion (toxic). Uses: Batteries, radiation shielding, soldering. Nickel Properties: Strong, ductile, corrosion-resistant. Uses: Stainless steel production, coinage, rechargeable batteries. Titanium Properties: Lightweight, strong, highly corrosion-resistant. Uses: Aerospace, medical devices, high-performance equipment. Importance of Metal Exports Economic Impact: Contributes to local and global economies by providing essential materials for various industries. Support for Infrastructure: Metals are foundational in construction, manufacturing, and technology sectors. Innovation: High-quality metals facilitate advancements in industries like aerospace, automotive, and electronics. If you have a specific metal or aspect of metals you’d like to explore further, feel free to ask! Understanding the metal needs of various industries can help identify trends, demands, and requirements in the market. Here are key considerations regarding metal needs across different sectors: 1. Construction Industry Steel: Strong demand for structural steel, reinforcing bars (rebar), and stainless steel for buildings, bridges, and infrastructure projects. Aluminum: Increasing use in facades, window frames, and roofing due to its lightweight and corrosion-resistant properties. Copper: Essential for electrical wiring, plumbing, and HVAC systems. 2. Manufacturing Steel and Aluminum: Widely used for manufacturing machinery, tools, and components in various industries. Brass and Copper: Commonly used for electrical connectors, fittings, and components. Alloys: Specialized alloys are needed for specific applications, including aerospace and automotive manufacturing. 3. Automotive Industry Aluminum and Steel: Critical for vehicle frames, body panels, and components, with a growing emphasis on lightweight materials to improve fuel efficiency. Nickel: Important for manufacturing stainless steel components and batteries. Copper: Required for electrical systems, including wiring and connectors. 4. Aerospace Industry Titanium: High demand for titanium components due to its strength-to-weight ratio and corrosion resistance. Aluminum Alloys: Used for aircraft structures and components. Specialty Alloys: Need for high-performance alloys that can withstand extreme conditions. 5. Electronics Copper: Vital for electrical wiring, circuit boards, and connectors. Gold and Silver: Used for plating and as conductive materials in high-quality electronic components. Aluminum: Increasingly used in housings and heat sinks due to its thermal conductivity. Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE Metals Exporter UAE 6. Energy Sector Steel: Essential for constructing pipelines, wind turbines, and other energy infrastructure. Copper: Critical for electrical applications in renewable energy technologies, such as solar panels and wind turbines. Nickel Alloys: Used in high-temperature and corrosive environments, particularly in oil and gas applications. 7. Marine Industry Aluminum and Steel: Used for shipbuilding and boat manufacturing due to their strength and resistance to corrosion. Copper-Nickel Alloys: Important for seawater applications due to their resistance to corrosion from saltwater. 8. Healthcare Stainless Steel: Commonly used in medical equipment, instruments, and implants due to its corrosion resistance and biocompatibility. Titanium: Increasing use in surgical implants and prosthetics. Factors Influencing Metal Needs Technological Advancements: Innovations in manufacturing processes and material science can lead to increased demand for specific metals. Regulatory Standards: Compliance with environmental regulations and standards can drive the need for sustainable and recycled metals. Market Trends: Shifts toward renewable energy, electric vehicles, and sustainable practices are reshaping metal demand across industries. Conclusion The metal needs of various industries are influenced by a combination of factors, including technological advancements, market trends, and regulatory standards. Understanding these needs can help businesses in sourcing, production, and innovation in the metal supply chain. If you have a specific industry or application in mind, I can provide more tailored insights! The benefits of using various metals across industries are significant and can greatly impact efficiency, sustainability, and product quality. Here’s a detailed overview of the benefits of using metals in different applications: 1. Strength and Durability High Strength-to-Weight Ratio: Metals like aluminum and titanium provide high strength without excessive weight, making them ideal for aerospace and automotive applications. Long Lifespan: Metals such as stainless steel and galvanized steel resist corrosion and wear, resulting in longer-lasting products and reduced maintenance costs. 2. Versatility Wide Range of Applications: Metals can be used in diverse applications, from construction and manufacturing to electronics and healthcare. Malleability and Ductility: Metals can be easily shaped and formed into various products without breaking, allowing for complex designs and structures. 3. Thermal and Electrical Conductivity Efficient Conductors: Metals like copper and aluminum are excellent conductors of heat and electricity, making them essential in electrical wiring and heating systems. Heat Resistance: Certain metals (e.g., titanium and nickel alloys) maintain performance in high-temperature environments, suitable for aerospace and automotive applications. 4. Recyclability Sustainable Practices: Metals like aluminum, steel, and copper are highly recyclable, reducing waste and energy consumption in production. Recycling metals conserves natural resources and decreases environmental impact. Circular Economy: The ability to recycle metals supports a circular economy by reintroducing materials back into the supply chain. 5. Cost-Effectiveness Lower Life-Cycle Costs: While some metals may have higher initial costs, their durability and low maintenance requirements can lead to lower overall life-cycle costs. Economies of Scale: Large-scale production and sourcing can reduce costs for industries that rely heavily on metal components. 6. Aesthetic Appeal Finishing Options: Metals can be finished in various ways (e.g., polishing, plating, anodizing) to enhance appearance and resistance to corrosion, making them popular in consumer products and architecture. Design Flexibility: The ability to create intricate designs with metals enhances the aesthetic value of products, particularly in the jewelry and luxury goods sectors. 7. Health and Safety Non-Toxic Options: Many metals, like stainless steel, are safe for use in food processing and medical applications due to their non-reactive nature. Reliability in Critical Applications: Metals are often chosen for their reliability in safety-critical applications, such as aerospace components and medical devices. 8. Innovation and Technology Advancements in Metallurgy: Ongoing research and development in metal alloys and processing techniques lead to the creation of high-performance materials tailored for specific applications. Smart Materials: Emerging technologies are integrating metals with smart capabilities, such as self-healing and responsive properties, enhancing their functionality in various industries. Conclusion The benefits of using metals span a wide range of factors, from mechanical properties and versatility to sustainability and cost-effectiveness. Understanding these benefits is crucial for industries to make informed decisions about materials, leading to improved product performance and environmental responsibility. If you’d like to explore a specific metal or application further, let me know! Here are the key characteristics of various metals that contribute to their suitability for different applications: 1. Aluminum Lightweight: Low density makes it easy to handle and reduces transportation costs. Corrosion Resistance: Forms a protective oxide layer, making it ideal for outdoor and marine applications. Malleability and Ductility: Can be easily shaped and formed into complex designs. Conductivity: Good conductor of electricity and heat, widely used in electrical applications. 2. Copper High Electrical Conductivity: The best electrical conductor among metals, widely used in wiring and electronics. Thermal Conductivity: Excellent heat conductor, ideal for heat exchangers and cooking utensils. Corrosion Resistance: Forms a protective patina over time, which prevents further corrosion. Malleability and Ductility: Easily drawn into wires or shaped into various forms. 3. Steel High Strength: Strong and durable, suitable for heavy construction and manufacturing. Versatility: Comes in various grades (e.g., carbon steel, stainless steel) for different applications. Weldability: Can be easily welded and fabricated into complex structures. Corrosion Resistance: Stainless steel, in particular, has excellent resistance to rust and corrosion. 4. Zinc Corrosion Resistance: Primarily used for galvanizing steel to prevent rust. Low Melting Point: Allows for easy casting and forming processes. Ductility: Can be shaped and drawn into various forms without breaking. Alloying Properties: Used to create various alloys, enhancing the properties of other metals. 5. Brass Corrosion Resistance: Excellent resistance to corrosion, making it suitable for plumbing and marine applications. Malleability: Can be easily shaped and formed, ideal for decorative and intricate designs. Ductility: Easily drawn into wires and made into various forms. Aesthetic Appeal: Has a bright, gold-like appearance, making it popular for decorative items. 6. Lead High Density: Heavy and dense, providing good shielding against radiation. Malleability: Easily shaped and formed, useful for applications like batteries. Corrosion Resistance: Resistant to corrosion in certain environments. Toxicity: Lead is toxic, requiring careful handling and regulation in applications. 7. Nickel Corrosion Resistance: Excellent resistance to oxidation and corrosion, particularly in harsh environments. Ductility: Can be drawn into thin wires and formed into various shapes. Strength: Provides strength and toughness to alloys, particularly in high-temperature applications. Magnetic Properties: Some nickel alloys have unique magnetic properties, making them suitable for electronic applications. 8. Titanium High Strength-to-Weight Ratio: Strong yet lightweight, ideal for aerospace and military applications. Corrosion Resistance: Excellent resistance to corrosion in extreme environments. Biocompatibility: Safe for use in medical implants and devices. Ductility: Can be shaped and formed, but more challenging to machine compared to other metals. Conclusion Each metal possesses distinct characteristics that make it suitable for specific applications. These properties, including strength, conductivity, corrosion resistance, and malleability, are essential for industries to consider when selecting materials for their products. If you have a particular metal or application in mind, feel free to ask for more detailed information! Here are some common myths about metals, along with explanations to clarify the truths behind them: 1. Myth: All Metals Are Heavy Truth: While some metals, like lead and gold, are dense and heavy, others, such as aluminum and titanium, are lightweight. This misconception often overlooks the varying densities of different metals. 2. Myth: Stainless Steel Doesn’t Rust Truth: While stainless steel is highly resistant to corrosion and rust due to the presence of chromium, it is not completely immune to rusting. Under certain conditions, such as exposure to chlorides or saltwater, stainless steel can corrode. 3. Myth: Aluminum is Weak Truth: Aluminum has a high strength-to-weight ratio and is often stronger than steel when alloyed with other elements. Its lightweight properties make it ideal for applications where weight is a critical factor, such as in the aerospace industry. 4. Myth: Copper is Only Used for Electrical Wiring Truth: While copper is well-known for its excellent electrical conductivity and is widely used in wiring, it also has applications in plumbing, roofing, industrial machinery, and even musical instruments. 5. Myth: All Metals Can Be Easily Recycled Truth: While many metals are recyclable, not all can be recycled with the same efficiency or ease. Factors like contamination, metal type, and market demand affect the recyclability of certain metals. 6. Myth: Lead is Safe in All Applications Truth: Lead is toxic and poses health risks, especially in applications where it can be ingested or inhaled. While it has historically been used in plumbing and paints, its use has been heavily regulated due to health concerns. 7. Myth: Metals Are Always Rigid and Brittle Truth: Many metals exhibit ductility and malleability, allowing them to be shaped without breaking. For example, gold is extremely malleable and can be drawn into thin wires. 8. Myth: Metal Fatigue Is Rarely a Concern Truth: Metal fatigue, the weakening of a material caused by repeatedly applied loads, can be a significant concern in many applications, especially in the aerospace and automotive industries. Regular inspections and maintenance are essential to mitigate this risk. 9. Myth: All Metals Are Magnetic Truth: Only a few metals, such as iron, nickel, and cobalt, are magnetic. Most metals, including aluminum and copper, are not magnetic. This misconception can lead to confusion in applications where magnetic properties are crucial. 10. Myth: All Metal Alloys Are Stronger Than Their Component Metals Truth: While many alloys are designed to enhance strength and other properties, not all alloys are stronger than their individual components. The specific properties of an alloy depend on its composition and the processes used to create it. Conclusion Understanding the truths behind these myths is essential for making informed decisions in metal selection, applications, and sustainability practices. If you have any specific myths or topics you’d like to discuss further, feel free to ask!