Office #207-2nd Floor-ZALFA BUILDING-NEAR Jumeirah Creekside Hotel-Garhoud -Dubai UAE

Machine oil exporter UAE MKK TRADE- Your Trusted Machine Oil Exporter

MKK Trade plays a significant role as an exporter of machine oils from the UAE, catering to diverse industries worldwide. With the growing demand for high-performance lubricants, MKK Trade has established itself as a reliable supplier of premium machine oils, designed to meet the needs of various sectors such as manufacturing, construction, automotive, and heavy industry.

The company ensures that its range of machine oils meets stringent international quality standards, offering products that enhance machinery performance, reduce wear and tear, and ensure longevity for industrial equipment.

MKK Trade’s machine oils are specifically formulated to provide superior lubrication, even under extreme operating conditions. These oils are engineered to perform well in high temperatures, heavy loads, and continuous operations, making them ideal for industries that rely on high-performance machinery.

By exporting high-quality oils, MKK Trade helps its clients achieve operational efficiency, reduce energy consumption, and minimize downtime caused by equipment failures.

Moreover, MKK Trade focuses on the environmental and economic aspects of its machine oil exports. Recognizing the global shift towards sustainable solutions, the company offers environmentally friendly options, including biodegradable machine oils that minimize environmental impact.

These oils are particularly sought after in industries where environmental regulations are stringent, such as marine, agriculture, and forestry. MKK Trade’s ability to provide such specialized products highlights its commitment to delivering solutions that not only enhance productivity but also align with environmental sustainability.

In addition to the quality of its products, MKK Trade ensures efficient logistics and timely delivery, making it a trusted partner for businesses around the world. The UAE’s strategic location as a global trade hub allows MKK Trade to facilitate the smooth export of machine oils to regions across the Middle East, Africa, Asia, and beyond.

By leveraging its expertise in international trade, the company continues to expand its footprint, serving both established markets and emerging economies that are looking for reliable sources of industrial-grade machine oils.

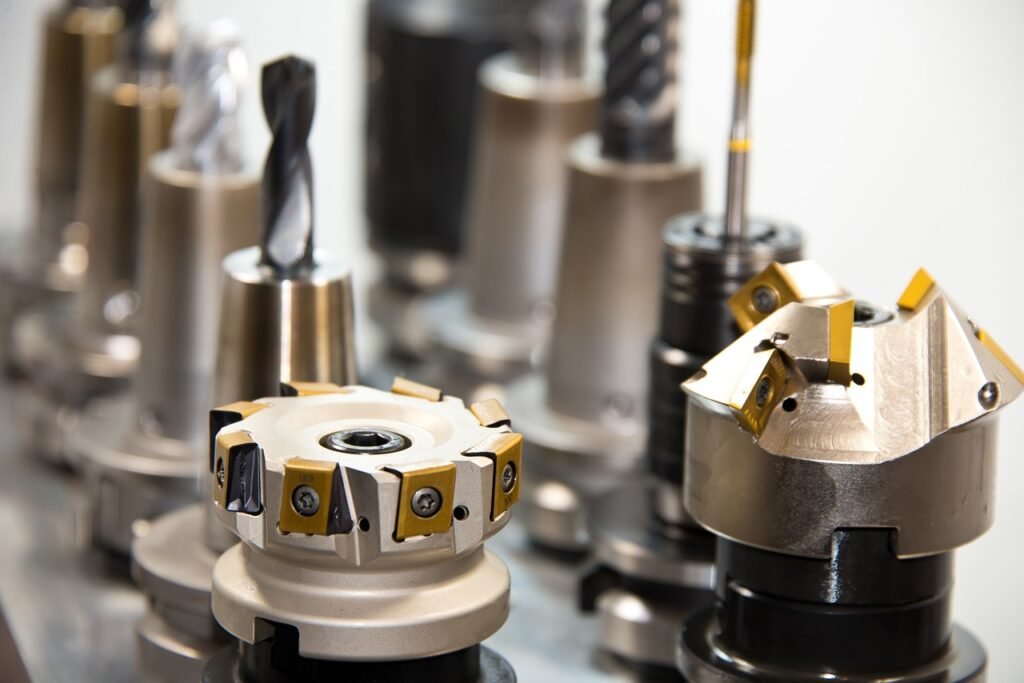

Machine oils, often referred to as industrial lubricants, play a critical role in ensuring the smooth operation and longevity of machinery across various industries. The key specialties of machine oils include:

1. Lubrication and Wear Protection

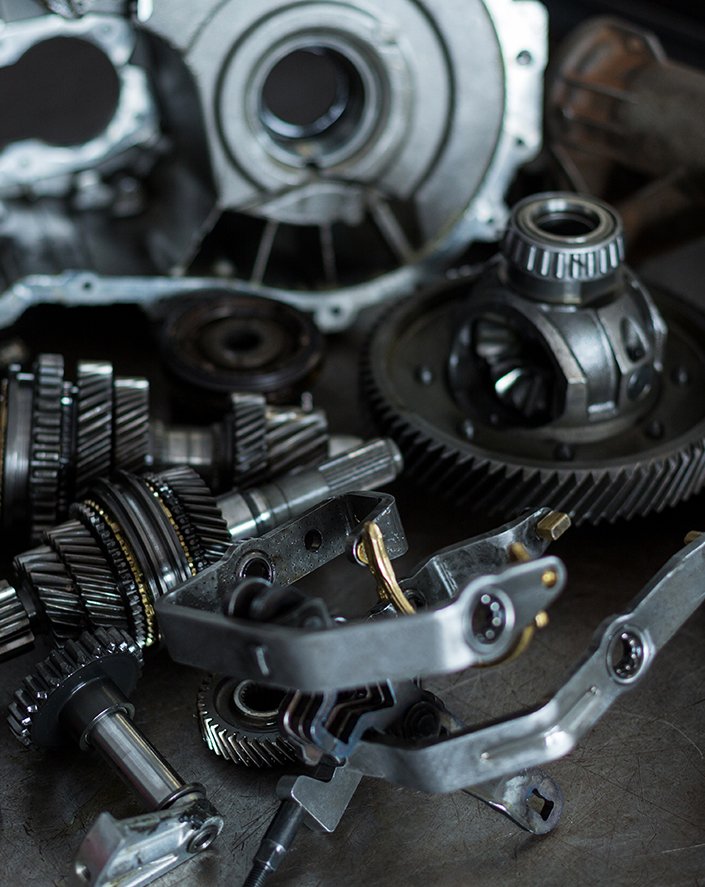

One of the primary functions of machine oils is to reduce friction between moving parts. This minimizes wear and tear, extending the life of machinery components like gears, bearings, and shafts. High-quality machine oils provide a protective film that prevents metal-to-metal contact, reducing mechanical degradation.

2. Heat Dissipation

Machine oils are formulated to absorb and dissipate heat generated during the operation of machinery. By cooling critical components, they help prevent overheating, which can cause malfunctions or reduce the efficiency of the machine. Heat dissipation is essential in high-performance or high-speed equipment.

3. Corrosion and Rust Prevention

Industrial environments often expose machinery to moisture, chemicals, or extreme temperatures, all of which can cause rust and corrosion. Machine oils contain anti-corrosion additives that form a protective barrier on metal surfaces, preventing oxidation and damage due to environmental factors.

4. Enhanced Machine Efficiency

By reducing friction and maintaining optimal temperature, machine oils help improve the overall efficiency of equipment. Less energy is lost to friction, and machinery can operate at its designed performance level for longer periods, leading to cost savings and increased productivity.

5. Oxidation Stability

High-quality machine oils offer oxidation stability, which means they are resistant to chemical breakdown over time. This ensures that the oil remains effective over longer intervals, reducing the need for frequent oil changes and improving the reliability of equipment.

6. Contaminant Control

Machine oils often contain additives that help control contaminants such as dirt, metal particles, or water that might accumulate in machinery. These oils help suspend and remove contaminants from the system, preventing them from causing damage to sensitive components.

7. Viscosity Stability

A key characteristic of machine oils is their ability to maintain a stable viscosity under varying temperatures and operating conditions. This ensures that the oil remains effective in providing lubrication, whether the machinery is operating in extreme cold or hot environments.

8. Compatibility with Different Machines

Machine oils are designed to be versatile and compatible with various types of machinery, including engines, compressors, gearboxes, and hydraulic systems. Different formulations are available to meet the specific needs of industries such as manufacturing, construction, transportation, and energy.

9. Energy Efficiency

By reducing friction and improving mechanical efficiency, machine oils can also contribute to energy savings. Efficient lubrication ensures that less energy is required to keep machinery operational, leading to reduced fuel or electricity consumption in industrial operations.

10. Specialized Formulations

Depending on the industry or machinery, machine oils can be specially formulated for particular applications. For example, oils used in high-pressure hydraulic systems differ from those used in high-speed gearboxes. Specialized machine oils may include synthetic lubricants, biodegradable oils, or fire-resistant options tailored to meet specific operational needs.

11. Environmentally Friendly Options

Many modern machine oils are designed with environmental considerations in mind. Biodegradable and low-toxicity oils are available for industries looking to minimize their environmental impact, especially in sensitive ecosystems like agriculture, marine, and forestry industries.

These specialties make machine oils indispensable for industrial operations, ensuring machinery performs optimally, is protected from damage, and has an extended lifespan.

Machine oils, also known as industrial lubricants, play a critical role in maintaining the efficiency, longevity, and performance of machinery across a broad spectrum of industries. Their fundamental function is to reduce friction between moving parts, ensuring that components interact smoothly without generating excessive heat or wear. Friction is one of the primary causes of machine deterioration, as it leads to the degradation of vital components like gears, bearings, and shafts.

Machine oils form a protective film on these surfaces, allowing for smoother operation, reducing energy loss, and extending the lifespan of the machinery. Without proper lubrication, machines would be prone to frequent breakdowns, leading to increased maintenance costs, more frequent replacements, and unplanned downtime, which can severely disrupt operations in sectors like manufacturing, automotive, and construction.

Another key role of machine oils is their ability to regulate temperature within mechanical systems. As machinery operates, especially in high-speed or high-load environments, it generates a significant amount of heat. If left unchecked, this heat can cause components to expand, warp, or even melt, ultimately resulting in catastrophic failures. Machine oils are designed to absorb and dissipate this heat, keeping the equipment within optimal temperature ranges.

By regulating the temperature, machine oils prevent overheating and maintain the operational stability of the machinery. This feature is especially important in industries where equipment runs continuously or under extreme pressure, such as in heavy-duty manufacturing, automotive production lines, and energy generation facilities. Proper temperature control also ensures that the machinery operates efficiently, without the risk of heat-related breakdowns.

In addition to reducing friction and controlling temperature, machine oils provide an essential layer of protection against corrosion and rust. Many machines are exposed to harsh environments where they come into contact with moisture, chemicals, and other corrosive substances. Over time, these elements can cause rust and corrosion, which weaken metal surfaces and compromise the integrity of critical parts. Machine oils contain additives that create a barrier on metal surfaces, protecting them from oxidation and chemical reactions that lead to corrosion.

This is particularly crucial in industries such as marine, agriculture, and mining, where equipment is often exposed to the elements. By preventing corrosion, machine oils help ensure that machines maintain their structural integrity and continue to operate reliably over time, thus reducing the need for expensive repairs or replacements.

Energy efficiency is another significant benefit provided by machine oils. By minimizing friction between moving parts, machine oils reduce the amount of energy required to keep equipment running. This not only enhances the performance of the machinery but also results in lower energy consumption.

For industries that rely on heavy machinery or equipment that operates for long periods, such as manufacturing plants and transport companies, this reduction in energy usage translates to substantial cost savings.

Furthermore, machine oils also help optimize the performance of hydraulic systems, gearboxes, and engines, making them operate more smoothly and with less strain. This improved efficiency allows businesses to increase their production capacity while reducing operational costs, contributing to higher profitability.

Machine oils also play a vital role in contaminant control within machinery systems. During operation, dirt, metal particles, and water can accumulate in the system and cause damage to sensitive components. These contaminants may lead to blockages, increased wear, and even mechanical failure if not properly managed. Machine oils are formulated with additives that help trap or dissolve contaminants, preventing them from circulating within the machinery.

By keeping internal components clean and free of harmful particles, machine oils reduce the risk of breakdowns and prolong the life of the equipment. This self-cleaning ability of machine oils is essential in maintaining the reliability and functionality of complex machinery, particularly in industries like manufacturing and automotive, where even minor failures can result in significant downtime and financial losses.

Moreover, machine oils are formulated to maintain their properties under varying conditions, including temperature fluctuations and high-pressure environments. This viscosity stability ensures that the oil remains effective in providing lubrication, regardless of changes in the operating environment. For industries operating in extreme climates or with heavy-duty equipment, such as construction, mining, or oil and gas, machine oils provide consistent performance even in challenging conditions. By offering reliable lubrication in both high and low temperatures, machine oils prevent mechanical failure due to viscosity breakdown, ensuring that equipment remains functional and efficient at all times.

In recent years, the environmental impact of machine oils has also gained importance, particularly as industries look for ways to reduce their ecological footprint. Many modern machine oils are now formulated to be biodegradable and low in toxicity, making them safer for use in environmentally sensitive areas like agriculture, marine, and forestry. Additionally, machine oils that contribute to energy efficiency indirectly reduce carbon emissions by lowering energy consumption.

This shift towards more sustainable lubrication options reflects a growing global trend toward eco-friendly industrial practices. Machine oils not only help industries maintain operational efficiency but also support efforts to minimize environmental impact, making them an essential component in the pursuit of sustainable development.

In conclusion, machine oils are indispensable in the world of industrial machinery and equipment. Their ability to reduce friction, regulate temperature, protect against corrosion, improve energy efficiency, and manage contaminants makes them critical to ensuring the smooth operation and longevity of machinery.

As industries continue to evolve and embrace more sustainable practices, machine oils will remain a key factor in driving efficiency, reducing costs, and maintaining reliable operations across various sectors. Without machine oils, modern industrial processes would be far less efficient, leading to increased downtime, higher energy usage, and more frequent equipment failures.

Industrial lubricants UAE Machine oil suppliers UAE Bulk machine oil UAE UAE lubricant importers Best machine oil exporter UAE Engine oil suppliers UAE Premium machine oil UAE UAE industrial oil wholesalers UAE machine oil manufacturers Industrial-grade machine oil exporter UAE Machine oil export to Dubai Hydraulic machine oil supplier UAE Lubricating oil for machines UAE Bulk industrial oil import regulations UAE High-performance machine oil for UAE industries Automotive machine oil supplier UAE UAE factory machine oil suppliers Synthetic machine oil exporters UAE UAE machine maintenance oil suppliers Best quality machine oil supplier in UAE Exporting industrial lubricants to UAE How to import machine oil to UAE Synthetic and mineral machine oil for UAE factories Top UAE distributors for industrial lubricants There are several common myths about machine oils, and they often lead to misconceptions regarding their usage, efficiency, and impact on machinery. Below are some of the most prevalent myths about machine oils, along with explanations to clarify the reality behind them. 1. Myth: All Machine Oils are the Same Reality: One of the biggest misconceptions is that all machine oils are identical, and you can use any oil for any type of machine. In reality, machine oils come in a wide variety of formulations designed for specific purposes and machinery types. The viscosity, additives, and base oil type vary depending on the application. For example, oils used in high-temperature industrial machinery differ significantly from those used in hydraulic systems or gearboxes. Using the wrong type of oil can lead to poor lubrication, excessive wear, or even damage to the machinery. 2. Myth: Machine Oils Never Need to Be Replaced Reality: Some people believe that machine oils can last indefinitely without needing to be changed. In fact, machine oils degrade over time due to oxidation, contamination, and exposure to extreme operating conditions. These factors reduce the oil’s effectiveness in lubricating and protecting machinery. Regular oil changes are essential to maintaining the performance of the equipment and preventing damage. Failing to replace oil at recommended intervals can lead to costly repairs and equipment failures. 3. Myth: Thicker Oil Provides Better Protection Reality: Many assume that thicker oils (with a higher viscosity) provide better protection for machinery. However, thicker isn’t always better. The right viscosity depends on the machine’s operating conditions. For example, high-viscosity oils may not flow as easily in cold conditions, leading to poor lubrication on startup, while low-viscosity oils may not provide adequate protection under heavy loads or high temperatures. The key is to use the correct oil specified by the manufacturer to match the machine's requirements. Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE v Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE vv Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAEMachine oil exporter UAEvv Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE Machine oil exporter UAE 4. Myth: Synthetic Oils Are Always Better than Mineral Oils Reality: While synthetic oils have several advantages, such as better performance in extreme temperatures and longer life, they are not necessarily better for all applications. Mineral oils, derived from crude oil, are often more cost-effective and provide sufficient protection in many standard operations. The choice between synthetic and mineral oils depends on the specific application, operating conditions, and the machinery being used. In some cases, using synthetic oil may be unnecessary or even overly expensive for the intended use. 5. Myth: Additives Are Not Important in Machine Oils Reality: Machine oils are formulated with various additives to enhance their performance. These additives can include anti-wear agents, corrosion inhibitors, viscosity improvers, and detergents. Some users believe that additives are unnecessary or don’t make a difference, but without these additives, machine oil would not be nearly as effective in protecting machinery from wear, oxidation, or contamination. Additives play a critical role in ensuring the oil performs well under specific operating conditions. 6. Myth: Once Oil Turns Dark, It Must Be Replaced Reality: The color of machine oil is not always an accurate indicator of its condition. While dark oil may indicate oxidation or contamination in some cases, oil can also turn dark simply due to the presence of certain additives or as a result of doing its job of cleaning and suspending contaminants. Instead of relying solely on color, it’s better to follow the manufacturer's recommended oil change intervals or have the oil tested for contaminants, viscosity, and other properties to determine if a replacement is necessary. 7. Myth: Using More Oil Improves Performance Reality: Over-lubricating machinery can be just as harmful as under-lubricating. Adding too much oil can lead to excess heat, pressure, and foaming inside the machinery. This can actually reduce the oil’s effectiveness in providing lubrication and cause leaks or damage to seals. It’s essential to apply the correct amount of oil, as specified by the equipment manufacturer, to ensure optimal performance and protection. 8. Myth: Oil Leakage is Normal and Unavoidable Reality: While oil leakage can occur over time due to worn seals or damaged components, it is not something that should be considered "normal." If a machine is leaking oil, it could be a sign of a serious issue that needs to be addressed. Regular maintenance and inspections can prevent leaks, and using high-quality machine oils that match the equipment’s specifications can reduce the likelihood of such problems. Ignoring oil leaks can lead to inadequate lubrication and increased wear on the equipment. 9. Myth: All Machine Oils Are Bad for the Environment Reality: While traditional machine oils can have negative environmental impacts if spilled or improperly disposed of, there are now biodegradable and environmentally friendly machine oils available. These eco-friendly oils are designed to reduce environmental harm, particularly in sensitive areas such as agriculture, forestry, and marine applications. They break down more quickly than traditional oils and have a lower impact on soil, water, and ecosystems. 10. Myth: Machine Oils Only Serve as Lubricants Reality: While lubrication is the primary function of machine oils, they also serve other important purposes. Machine oils help in heat dissipation, preventing overheating in critical components. They also play a role in contaminant control by suspending particles, preventing them from accumulating on surfaces or causing damage. Additionally, machine oils protect against rust and corrosion, extending the life of machinery, especially in environments where moisture or chemicals are present. In conclusion, machine oils are much more complex than many people realize, and their proper use is essential for maintaining the longevity and efficiency of machinery. Understanding the differences between types of oils, their additives, and the correct application methods is key to avoiding these common myths and ensuring optimal machine performance.